PTS

UK The continual increase in technological and design equipment in workplaces (electrical, telephone and IT networks, heating systems and air conditioning systems) and research into optimising operativity and the wellbeing of workers has led to a growing trend in raised flooring; above and beyond arranging and moving cables and pipework freely.

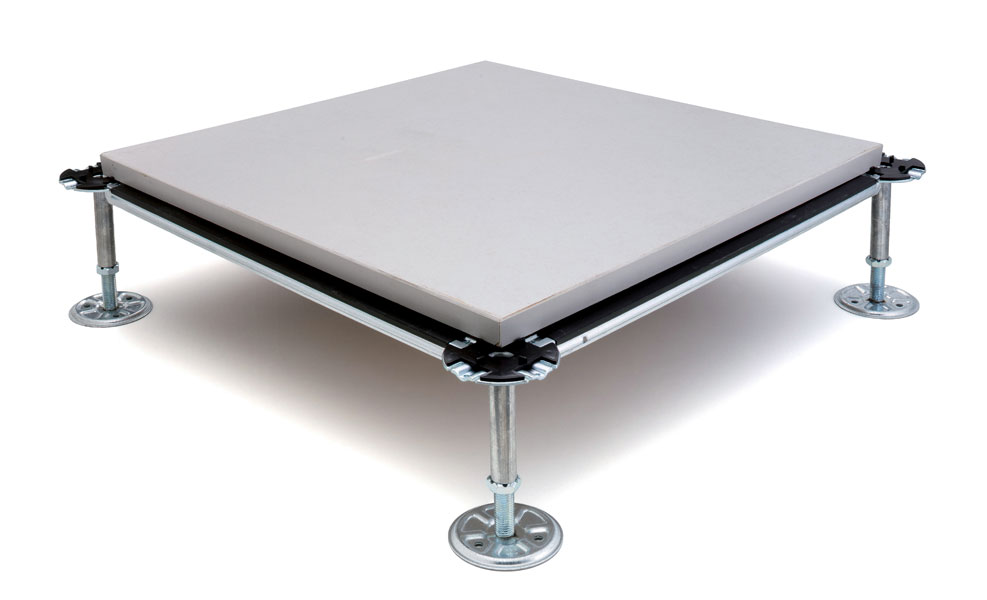

PTS is the profession system for indoor raised flooring Made in Mirage® and involves a flooring system raised onto metal structures using supported, removable modules that create a space for design.

The special feature of this system is its functionality; it allows you to access systems and operate them without having to intervene in the wall structure. This provides unquestionable savings in terms of time and management costs.

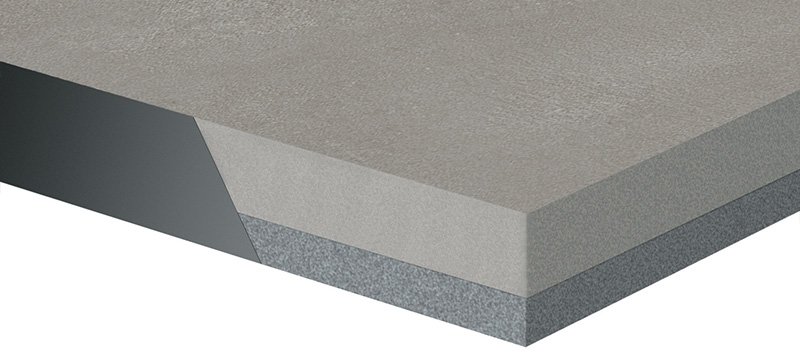

PTS is made up of two main parts: panels and a substructure.

The panel creates a connection between the support and the stoneware strip of the cover that forms the footboard. This ensures aesthetic quality and excellent stability and resistance over time.

The purpose of the substructure is to support the footboard and transfer stress placed on it to the screed underneath. As the panels are installed dry (without glue) on site, it is possible to intervene on each floor panel to move them. Also, all components can be reused at a later time in different rooms to those in which the floor was originally installed. The type of installation used for the panels also ensures that they can be disposed of at the end of their useful life in a way that has no impact on the environment.

Components

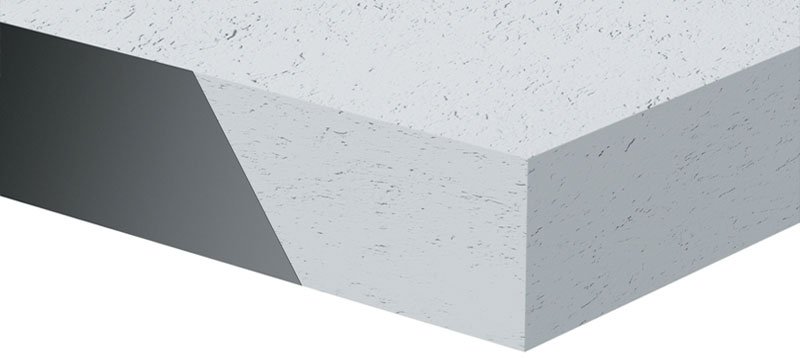

1. Upper covering in porcelain stoneware

The upper covering - in Mirage® porcelain stoneware - can be used in various finishings produced to ensure the best solution for each situation. The porcelain stoneware is fitted to the structural core. The panel created in this way is ground to create a flare of approximately four degrees towards the inside and towards the bottom. This operation is required to allow the panels to be installed and removed easily.

The consequent grinding of the porcelain stoneware strip, together with the structural core, provides very accurate sides that allow you to use small sized edges, making them less visible but extremely efficient in protecting the panel itself and the seal between the various panels. Panels of various shapes can be produced alongside the 60x60 shape. These include: 45x45, 30x60, 60x120 and 30x120.

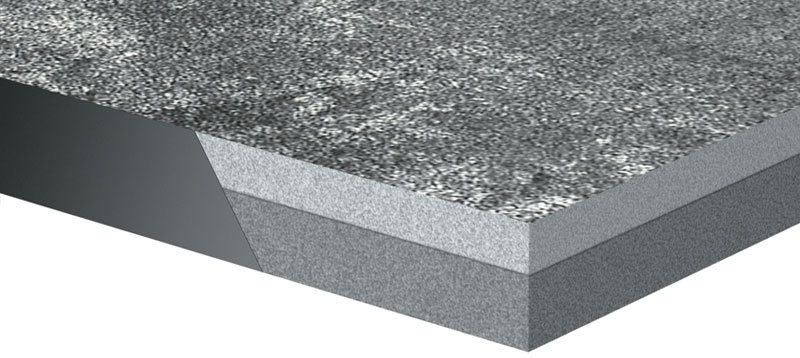

2. Structural core

The structural core is the base on which the porcelain stoneware slabs are fixed. Mirage® uses 4 types of products, depending on the specific requirements of the project.

5. Structure

In raised floors, the structure means the portion that is installed onto the floor, creating a void gap in order to reach the desired height of the raised floor.

This structure is the load-bearing element of the raised floor consisting of vertically adjustable feet and junction beams. Metallic structures are made of galvanised steel and can be used for raises from 60mm to 1 metre and over. The head of the feet and beams are covered with soundproof and antidust plastic and non-conductive material.

Upon request, they are also available in conductive material should the project and ambient specifications require it.

6. Tubular structure

The tubular structure is a special type of support that is suitable for high load-bearing requirements. It is composed of special adjustable columns designed to lodge rectangular beams passing onto the head of the column and fixed to it using threaded screws. Closed-section galvanised beams of 50x25mm come with an adhesive gasket with anti-dust and soundproofing features.

This structure transfers the noise generated by the floor. In order to reduce the noise transferred to the lower floors and also to reduce the reflected noise, 100x100mm square panels of soundinsulating material such as rubber and/or cork with a thickness between 3 and 10 mm are used. These systems, supplied upon request and following a specific acoustic calculation make the raised floor more comfortable thus maintaining its technical features.

7. Accessories

A series of accessories complete the raised floor solution in order to meet the most varied needs: suction cups to remove panels, accessories for the installation of the structure such as plugs for the fixing of feet, screws for the fixing of the structure, adhesive for the gluing of feet, additional structures for the fixing of feet on the floor or wall. The list of accessories also includes access ramps and aluminium steps and air-circulation grids.