Specifications

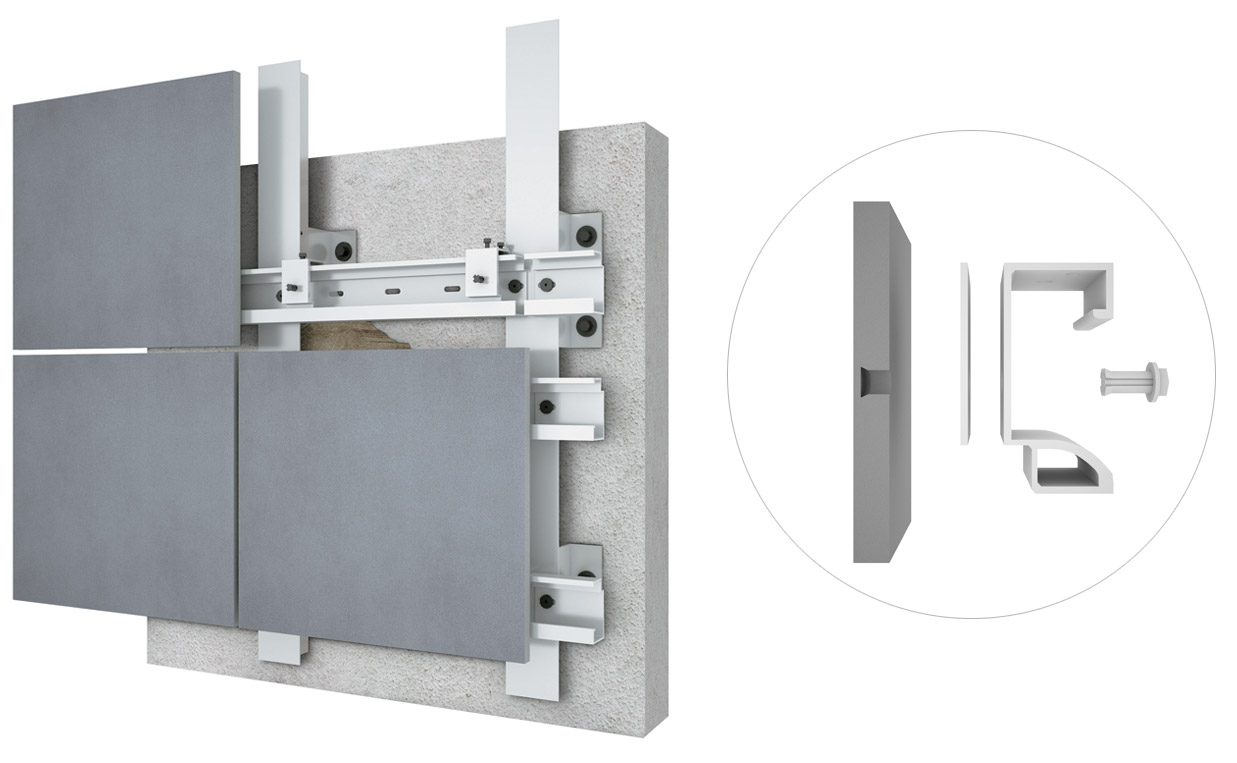

The structure is made up of profiles and brackets manufactured via the extrusion of aluminium alloy, with a minimum thickness of 2 mm.

The structure will be tied to the support in order to absorb thermal expansion/shrinkage and subsidence of the support itself so that the external covering is not affected by any possible future induced stress.

The safety of the system must be guaranteed via a subsequent check for every single project, in accordance with the norms relating to wind pressure/depression.

Specific description of the system

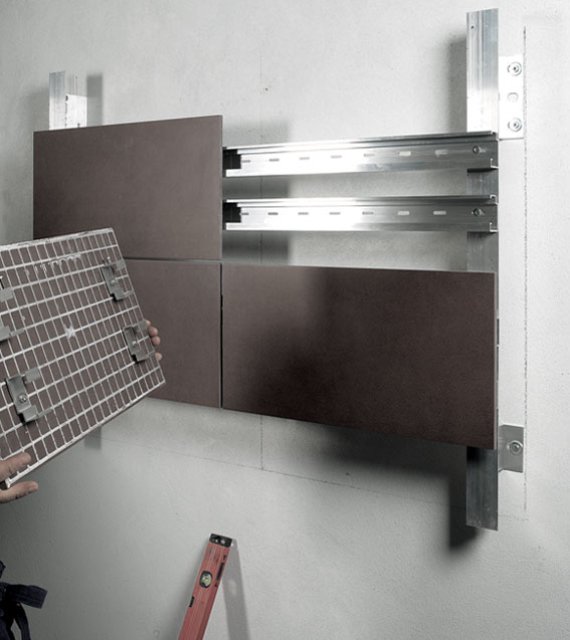

The fixing of the brackets to the underlying support must be carried out using adequately sized plugs suitable for the specific type of support. The fixing of profiles onto the brackets will be carried out using rivets with “fixed point” and “sliding point” depending on the project specifications.

Horizontal looped profiles will then be anchored to the vertical profiles, these horizontal profiles will be duly sized so that the stress due to the action of wind is axial with respect to the clips.

This system calls for the slabs to undergo mechanical manufacturing on the back of them and the subsequent introduction of special steel inserts.

This device has been designed for the anchorage of the clips that will be then fixed to the horizontal profiles.